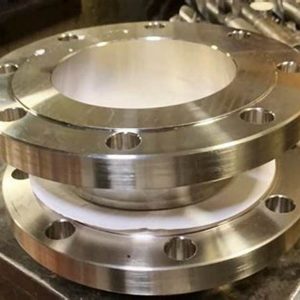

ASTM A105 Specification

| Name: | ASTM A105 Specification |

| Specificaiton: | ASTM A105 |

| Size:: | 1/2″ to 60″ |

| Rating: | 150 to 2500 |

| Steel Grade: | A105 |

| MOQ: | 100 KGS |

| Seal Face: | RF, RTJ, FF |

| Delivery term: | FOB, CNF, CIF and EXW |

| Payment Term: | TT or LC At sight |

| Loading Port: | XINGANG |

| Deliver mode: | By Sea, By Air and By Land |

| Packing: | Standard seaworthy/airworthy packing |

| Standard: | ANSI, JIS, BS, EN, DIN |

Category: Weld Neck

Description

Product Description

ASTM A105 SPECIFICATIONS

A105

Scope

ASTM A105 (also known as ASME SA 105) Cangzhou wilson pipeline sales@wilsonpipeline.com covers seamless forged carbon steel piping components for use in pressure systems at ambient and high-temperature service.

Flanges, fittings, valves and various other parts ordered to customer dimension or to industry standards such as MSS, ASME and API specification are included in the scope.

Forgings to this specification are limited to 10,000 lbs.

Welding

These components can be welded. Welding procedures must comply with ASME Boiler and Pressure Vessel Code Section IX.

Heat Treatment

Heat treatment is not a mandatory requirement except for flanges above Class 300, flanges of special design where the design pressure or design temperature are not known and for items over 4” NPS and above Class 300. When heat treatment is required, annealing, normalizing, normalize and temper, normalize and quench and tempering shall be the applied methods.

Forging

This alloy is forged at between 1,700 degrees Fahrenheit and 2,200 degrees Fahrenheit, followed by quenching and tempering.

Annealing

Forged parts are allowed to cool to below 1,000 degrees Fahrenheit before reheating to between 1,550 degrees Fahrenheit and 1,700 degrees Fahrenheit. Slow furnace cooling follows.

Chemical Composition

| Element | Composition %, Note C |

|---|---|

| Carbon | .35 max |

| Manganese | .60-1.05 |

| Phosphorus | .035 max |

| Sulfur | .040 max |

| Silicon | .10-35 |

| Copper | .40 max, note A |

| Nickel | .40 max, note A |

| Chromium | .30 max, note A,B |

| Molybdenum | .12 max, note A,B |

| Vanadium | .08 max, note A |

| Note A – The sum of copper, nickel, chromium, molybdenum and vanadium shall not exceed 1.00% Note B – The sum of chromium and molybdenum shall not exceed .32% Note C – for each reduction of 0.01% below the specified carbon maximum (.35%), an increase of .06% manganese above the specified maximum (1.05%) will be permitted up to a maximum of 1.65% |

|

Mechanical Properties

| Tensile | 70 ksi, min |

| Yield, note A | 36 ksi, min |

| Elongation in 2in, Basic minimum for wall 5/16″ and over, strip test | 30% |

| Hardness | 187 HBW max |

| Note A – Determined by either the 0.2% offset method or the 0.5% extension-under-load method. Other test methods available as listed in A105. | |

Hydrostatic Test

Hydrostatic Test shall be conducted by the forging manufacture only when Supplemental S57 of ASTM A961 is specified.

Reference Documents

- A266/A266M Specification for Carbon Steel Forgings for Pressure Vessel Components

- A675/A675M Specification for Steel Bars, Carbon, Hot-Wrought, Special Quality, Mechanical Properties

- A696 Specification for Steel Bars, Carbon, Hot-Wrought or Cold-Finished, Special Quality, for Pressure Piping Components

- A788/A788M Specification for Steel Forgings, General Requirements

- A961/A961M Specification for Common Requirements for Steel Flanges, Forged Fittings, Valves, and Parts for Piping Applications

- MSS Standard – SP 44 Standard for Steel Pipe Line Flanges

- B16.5 Dimensional Standards for Steel Pipe Flanges and Flanged Fittings

- B16.9 Wrought Steel Buttwelding Fittings

- B16.11 Forged Steel Fittings, Socket Weld, and Threaded

- B16.34 Valves-Flanged, Threaded and Welding End

Shipping & Delivery

Free Delivery

Orders from 70,00 Euro will be shipped free of charge within Germany and to Austria with GLS! Up to 69,99 Euro order volume we charge only 3,90 Euro with GLS. For shipment with DHL GoGreen within Germany we charge only 5,90 Euro up to 69,99 Euro order volume or 2,00 Euro for orders from 70,00 Euro.

Delivery Time: Ready for Shipping within 24h

We try hard to make as much orders as possible ready for shipping within 24 hours (after receiption of payment), because we generally offer only items in our online shop which we have currently on stock. The independent official seal for excellence in shipment always shows you, have fast we are currently working (make your order ready for pick-up by our logistics partner).

Delivery areas:

We deliver to the following countries:

Germany, Austria, Switzerland and Belgium, Bulgaria, Denmark, Estonia, Finland, France, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Liechtenstein, Luxembourg, Netherlands, Norway, Poland, Portugal, Romania, Russia, Sweden, Switzerland, Slovakia, Slovenia, Spain, Czech Republic, Hungary, USA. Please find information about delivery costs below. We usually do, but currently do NOT ship to: UK and Norway. Please visit this site frequently for updates or contact our customer service.

Returns

If a product does not meet your expectation for any reason, you can return the product without ifs and buts. To make it even more easy for you, we recommend to use the attached return form and the return stickers free of charge within 30 days of receipt. Just drop the parcel at your nearest GLS parcel shop or DHL branch (depending on the provided return label) in Germany. Of course this is not a compulsory requirement to exercise your right of withdrawal. Find more information on our website for your right of withdrawal.