Wilson Pipeline is a leading manufacturer and distributor of flange fittings material from alloy steel stainless steel to carbon steel.products, including Super Duplex Stainless Steel Flanges, Stainless Steel Flanges, Stainless Steel Pipe Fittings. ASME B16.5 ASME B16.9 ASME B16.11 EN1092,ANSI ASTM,GOST,JIS,DINWilson Pipeline products are widely used in Shipbuilding, Nuclear power, Marine engineering, Petroleum, Chemical, Mining, Sewage treatment, Natural gas and Pressure vessels and other industries.If you want to have more information you want to share your enquiry with us, contact us at sales@wilsonpipeline.com

Description

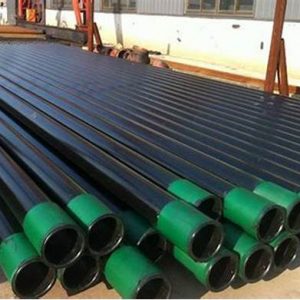

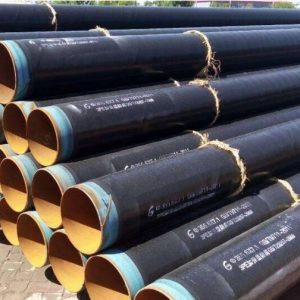

API 5L is a specification which adheres to the standard for the ISO 3183. The materials, produced under this specification, say the API 5L Grade B Seamless Pipe are typically used in the transportation of various fluids and gases.

For instance, the specified API 5L Grade B Carbon Steel Pipe is generally used in applications involving industries such as petroleum, petrochemical, as well as the natural gas industries. One such instance, where the API 5L Grade B PSL1 Material proves to be particularly useful is when they are used in sour wells. In fact, the API 5L specification Schedule 40 Grade B Pipe tend to be well suited for use in sour service, because the API 5L Grade B Erw Pipe has the ability to resist sulphide stress related cracking. Usually in sour service wells, conventionally used carbon steel popes are susceptible to cracking, due to deposition of Hydrogen sulphide on the inner layer of these pipes. Hydrogen sulphide, deposited on the inner walls of the API 5L Grade B Pipe makes steel pipes brittle. Since hydrogen sulphide gas reacts with water, as a result of which the free hydrogen molecule gets deposited in the inner walls of conventional steel pipes, thereby leaving it brittle. Addition of elements such as, Molybdenum and chromium can raise the resistance levels of the API 5L Gr B Pipe to both cracking and corrosion as well. Apart from offering these properties, the API 5L Grade B PSL2 pipes are known to have a rigid and compact design along with the Grade B Welded Pipe having precise and stable dimensions, properties which make them attractive. The Grade B Dsaw Pipe can also be machine bored. Additionally, the Sch 80 Grade B Pipe offers optimum efficiency whilst bearing pressure.

API 5L Grade B Specification

| Grade of material | Grade A L210/ Grade B L245 (N, M, Q, R) |

| Standard | ISO 3183 L245/ Gr. B |

| Seamless Pipe (OD) | 21.3 – 660mm ( Inch 1/2” – 26”) |

| L245 Grade B SAW | 16″ – 100″ NB |

| API5LB LSAW / DSAW | 16’OD TO 54″ OD (8 MM TO 50 MM THK) |

| Pipe end | Flanged Ends, Square Cut, Cut Grooves, Coupling, Thread Cutting, Grooved, Beveled End (BE), Pub Joints, Chamfering, Deburring, Threaded Ends (Male & Female), Buttweld, Screwed, Squared Ends, Plain end (PE), Socket, Vibrator Grinding |

| PSL2 ERW and HFW | 1/2” NB – 24” NB |

| API 5L Grb Pipe Length | DRL, SRL, 20FT, 40FT, Single Random Length (SRL), Double Random Length (DRL), and Fixed Length 5.8 Meter, 12.0 Meters (40FT), 6.0 Meters (20FT), 11.8 Meters, |

| Wall Thickness | SCH-XXS, SCH160, SCH40, SCH-STD, SCH80, SCH-XS |

| PSL (Product Specification) Level |

|

| Coating | Galvanized, 3PP, Anti-Rust Oil, Varnished, Black Painting, FBE, CRA clad, lined pipe, 3LPE, 3PE |

| Approvals | ONGC, IBR, Merkblatt W0, BP, PED 97/23/EC, NORSOK M-650, KNPC, HAF 604, Saudi Aramco, AD2000, Shell, L&T, ISO 17025 for Laboratories, EIL, PED |

| Leading API 5L Grade B Pipe manufacturers | Arcelormittal, TATA Steel, JFE, Interpipe, United Seamless Tubulaar Pvt. Ltd (USTPL), Sumitomo Corporation, Indian Seamless Metal (ISMT), TMK, Boly Pipe, Benteler, Maharshtra Seamless Limited (MSL), Jindal Saw Limited (JSL) |

| Origin of L245 Grade B material | Indian, Gulf, USA, Chinese, American, Asian, Korean, Africa, Ukraine, Japanese, European, Russian, Japan, Latin-American, UK |

| Manufacturing methods | Horizontal Submerged Arc Welded (HSAW), Submerged Arc Welded (SAW), Hot Finish Seamless (HFS), Welded, Longitudinally Submerged Arc Welded (LSAW), Electric Resistance Welded (ERW), Cold Drawn Seamless (CDS), Seamless, Electro Fusion Seam Welded (EFSW), Extrusion |

| Certificates | HIC, NACE, SSC, EN-10204:3.1, Sour-Service, EN-10204:3.2, IBR |

| Equivalent Standards | UNI, NFA, SS, EN, BS, CSA, ISO, ASTM, DIN, KS, AWWA, GB, GOST, JIS, IS, API, ANSI, AISI, SAE |

| Cutting Facility | Sawing, Laser Cutting, Tapping, Water Jet Cutting |

| Test | Macro, Fine Grain, Impact, Bend TestBend test / Guided Bend, TM0284, IGC- Intergranular Corrosion Test, Stress , Charpy V-Notch Test, Eddy current, Flux Leakage examination or Magnetic Flaw detection, Hardness Test, Creep, Ultrasonic Test, Surface Roughness Test, NACE MR0175, Hydro test, Ultrasonic, IBR, Hardness, Straightness, Chemical, Charpy V Impact Test, Non Destructive Testing , Tensile, Burst Test, Micro, TM0177, Radiography, SSC- Sulfide Stress Corrosion Cracking, Metallurgical & Stereo Microscopy, Ferrite, Salt Spray Test to test Phosphating, HIC- Hydrogen-induced Cracking, Mechanical, Positive Material Identification (PMI), H2 SERVICE |

| Material Test Certificate (MTC) | destructive, EN 10204 3.1, ISO10893-8, API 2B, ASTM A252, Ultrasonic Testing (UT), NACE MR0175, Radiographic Testing (RT), nondestructive, E/I, N5, NDE, NACE MR0103, EN 10204 3.2 |

Shipping & Delivery

Free Delivery

Orders from 70,00 Euro will be shipped free of charge within Germany and to Austria with GLS! Up to 69,99 Euro order volume we charge only 3,90 Euro with GLS. For shipment with DHL GoGreen within Germany we charge only 5,90 Euro up to 69,99 Euro order volume or 2,00 Euro for orders from 70,00 Euro.

Delivery Time: Ready for Shipping within 24h

We try hard to make as much orders as possible ready for shipping within 24 hours (after receiption of payment), because we generally offer only items in our online shop which we have currently on stock. The independent official seal for excellence in shipment always shows you, have fast we are currently working (make your order ready for pick-up by our logistics partner).

Delivery areas:

We deliver to the following countries:

Germany, Austria, Switzerland and Belgium, Bulgaria, Denmark, Estonia, Finland, France, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Liechtenstein, Luxembourg, Netherlands, Norway, Poland, Portugal, Romania, Russia, Sweden, Switzerland, Slovakia, Slovenia, Spain, Czech Republic, Hungary, USA. Please find information about delivery costs below. We usually do, but currently do NOT ship to: UK and Norway. Please visit this site frequently for updates or contact our customer service.

Returns

If a product does not meet your expectation for any reason, you can return the product without ifs and buts. To make it even more easy for you, we recommend to use the attached return form and the return stickers free of charge within 30 days of receipt. Just drop the parcel at your nearest GLS parcel shop or DHL branch (depending on the provided return label) in Germany. Of course this is not a compulsory requirement to exercise your right of withdrawal. Find more information on our website for your right of withdrawal.